OFFER & USE OF UV DISINFECTION IN FISH FARMING

UV disinfection system is a sterilizing device for biologically charged water treatment, where the Ultra Violet radiation targets directly to microorganisms genetic material (DNA & RNA) destruction. The comparative advantage of the UV disinfection system over various chemical disinfection methods, is the unaffected physical and chemical composition of water after the UV radiation activity. The UV is effective against any type of microorganism such as algae, bacteria, virus, fungi, yeasts and ozone gas.

UV devices are core filters to biologically charged water volume and it is commonly used to fresh and marine RAS farms and hatcheries.

APPLICATION of UV STERILIZERS in AQUACULTURE

UV sterilization is applied as a supportive filtration method to biological and mechanical filters of biologically charged water. They are suitable for hatcheries and fish farms as well as other aquaculture applications.

OPERATION & ENGINEERING OF AQUACULTURE UV STERILIZERS

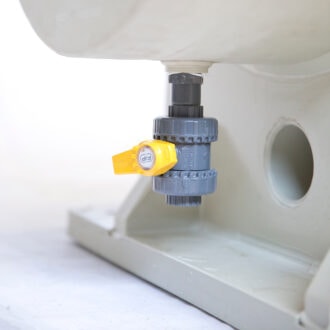

After biological filtration, water flows into the UV disinfection chamber, where Ultraviolet Radiation is emitted to destroy the genetic material of microorganisms contained in the water. Moreover, MAT-KULING low pressure UV devices, are capable of multi-frequency emission, resulting in more than 50% chloramines elimination through a photochemical reaction. The Aquaculture UV sterilizers are made of PE or HDPE on demand resistant to osmosis. The systems come with control panel to monitor the operation and effectiveness of the UV lamps.

ADVANTAGES OF AQUACULTURE UV DISINFECTION SYSTEMS

- Maintaining Unaffected Physical & Chemical Composition of the Water

- Effective against any Type of Harmful Microorganism

- Minimized Risk of Handling & Dosing Hazardous Chemical Products

- Avoidance of Hyper Chlorination