NOORDZEE Project Scope of Work

Installation of intensive RAS equipment for the Sea Bass and Sea Beam growing tanks. Noordzee is one of the leading aquaculture companies in Turkey that specializes in the production and export of Sea Bream, Sea Bass, and Stone Bass. With 100 % of the fish farms located offshore and an annual production capacity of approximately 8,000 tons, Noordzee has accomplished to become one of the primary exporting companies of the sector in Turkey.

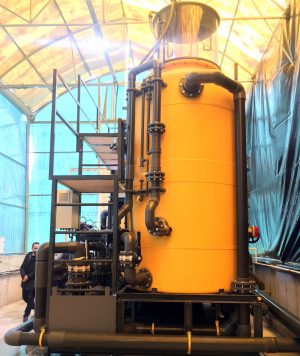

MAT-KULING was selected by Noordzee to supply all the Recirculating Aquaculture Systems for their new fish tanks. The equipment was installed in their hatchery located in the town of Güllük, in the southwestern Aegean region of Turkey. The project consisted of 9 tanks in total, with a volume capacity of 50 m³ each and a maximum fish bio-load between 4000 and 5000 kg per RAS system. Besides these, the project also comprised the design and installation of several types of RAS and RAS equipment for their Larva, Growing and Brood Stock tanks with complete automation and control systems which allowed to monitor all the tank conditions providing an optimal production. Noordzee is another company that puts its confidence in MAT-KULING experience.

Aquaculture Services, Engineering & Equipment

MAT-KULING provided site analysis, system planning, equipment design, manufacture and supply, equipment installation and commissioning services and technical training to operations staff.

The installed equipment consisted of 5 RAS Skids model 1500, 1 RAS Skid model 500, 1 Compact model 10 and 5 Protein Skimmers model 500. Each RAS SKD-1500 unit included a protein skimmer PS-1500 with a flow rate of 160 m³/h, a mechanical pressurized glass media filter with a total flow rate of 65 m³/h, a biological RAS trickle filter T-1500 with a 160 m³/h flow rate, an ozone generator OZ-10 with a maximum ozone output of 10 g/h and a UV disinfection unit PE-110 supplying a flow rate of 110 m³/h.

The RAS SKD-500 unit included a protein skimmer PS-500 with a flow rate of 10.6 m³/h, a mechanical pressurized glass media filter with a total flow rate of 65 m³/h, a biological trickle filter T-500 with a 10 m³/h flow rate and UV disinfection unit PE-15 supplying a flow rate of 15 m³/h. In addition to this, a full customized compact filtration unit CPT-10 with a total flow rate of 10 m³/h and five extra protein skimmers PS-500 with flow rates of 10.6 m³/h were supplied. All units comprised a set of accessories & internal piping, valves, pumps, and instruments.